1. Overview

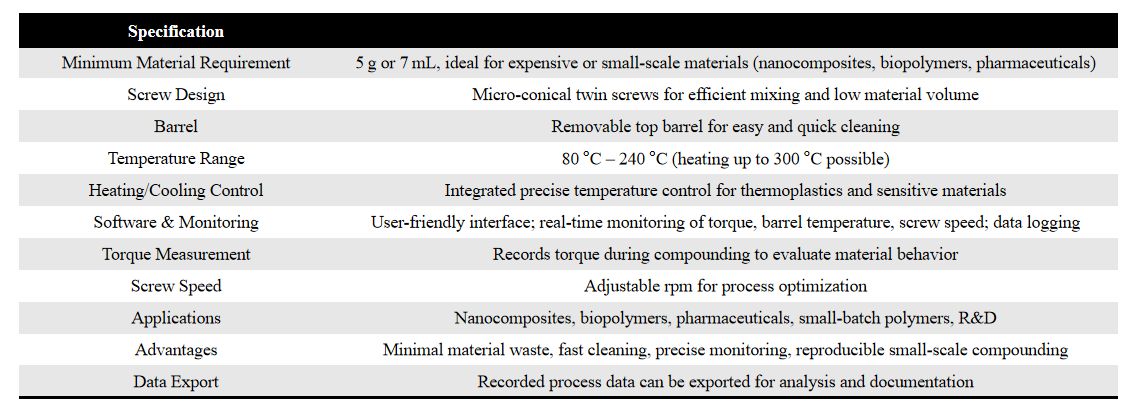

Thermo Scientific HAAKE MiniCTW is a conical twin-screw compounder designed for low-volume polymer blending, compounding, formulation optimization, and material screening.

It is specifically built for situations where material availability is limited, requiring only 5–7 g of sample per run, making it ideal for R&D, high-value polymers, additives, pharmaceuticals, and academic research.

Features

- Requires only 7 mL of material for compounding

- Removable top barrel for easy and quick cleaning

- New software for user-friendly process monitoring

- Recorded data: torque, temperatures, speed

2. Principle

The MiniCTW uses conical corotating twin screws housed in a temperature-controlled mixing chamber. Material is fed into the chamber where shear, distributive mixing, and dispersive mixing occur as the screws rotate.

- Torque vs time: indicators of melt rheology, gelation, fusion, and filler interaction

- Melt homogeneity: blending quality and dispersion

- Thermal stability: changes during residence time

- Processability: ability to mix, compound, and plastify at specific temperatures

Because only grams of material are needed, it enables early-stage formulation decisions with minimal waste.

3. Data Interpretation

Typical data readings

- Torque curves: reflect polymer melting, additive fusion, or filler incorporation

- Equilibrium torque: relates to melt viscosity and stability

- Mixing time to torque plateau: indicates processability and compatibility

- Batch uniformity: judged through visual and torque stability

Interpretation notes

- Higher torque suggests higher melt viscosity or strong filler interactions

- Decreasing torque may indicate thermal degradation or plasticization

- Fast torque stabilization suggests efficient mixing and compatibility

- Comparative torque profiles help evaluate different formulations or additives

4. Example Applications

- Polymer blends and alloys: miscibility and compatibility screening

- Masterbatches: dispersing pigments, carbon black, and nanoparticles

- Additive optimization: stabilizers, plasticizers, lubricants, flame retardants

- Biopolymers and degradable plastics: melt processing feasibility

- Elastomers and TPEs: soft-segment interaction under shear

- High-value materials: fluoropolymers, engineering plastics, medical polymers

- Pharmaceutical hot-melt extrusion precursors: drug–polymer compatibility