KSV NIMA medium LB Trough

Available accessories: Brust Angle Microscopy, Surface Potential Sensor

1. Overview

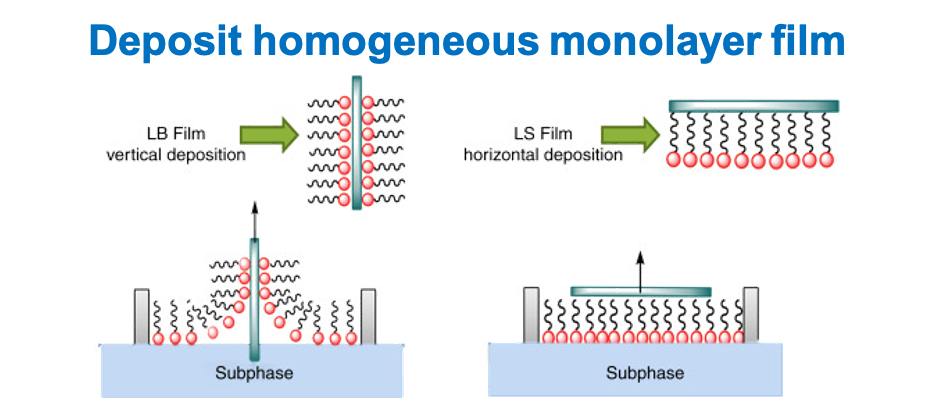

Langmuir–Blodgett (LB) Technique:

- LB is a method to transfer monolayers or multilayers of amphiphilic molecules from the air–water interface onto solid substrates vertically.

- Widely used to fabricate well-ordered thin films for electronics, sensors, optics, and nanomaterials.

Langmuir–Schaefer (LS) Technique:

- LS is a horizontal deposition technique where a monolayer at the air–water interface is transferred horizontally onto the substrate.

Especially suitable for fragile or sensitive monolayers and substrates that cannot withstand vertical dipping.

Features

Features

2. Principle

LB Principle:

- Amphiphilic molecules (hydrophilic head, hydrophobic tail) form a monolayer at the air–water interface.

- Compression controls surface pressure and molecular packing.

- A substrate is vertically dipped through the monolayer, transferring the film onto the solid surface.

- Repeated dipping builds multilayer films with controlled thickness.

LS Principle:

- Similar monolayer formation and compression on a Langmuir trough.

- Substrate is touched horizontally onto the monolayer, lifting the film gently onto the substrate.

- Maintains molecular orientation and minimizes stress on delicate films.

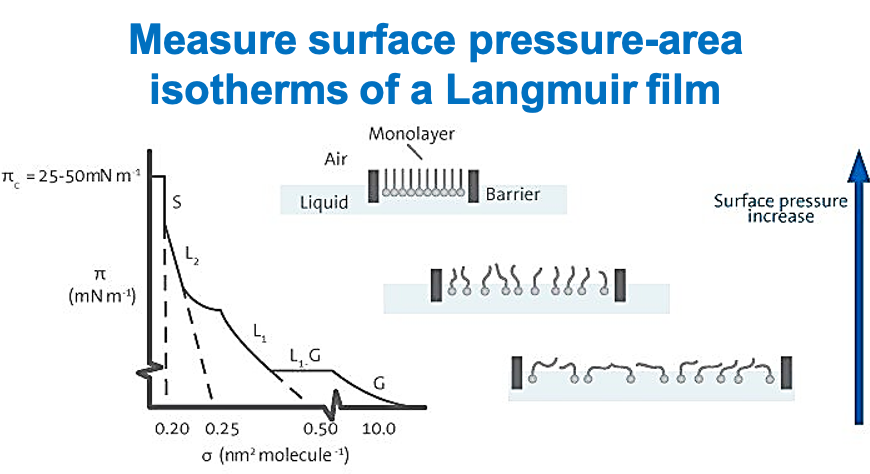

3. Data Interpretation

Film Characterization after Transfer (LB & LS):

- Thickness / Layer number: Monitored by ellipsometry, AFM, or X-ray reflectivity.

- Surface morphology: Atomic force microscopy (AFM) or scanning electron microscopy (SEM) can reveal uniformity and defects.

- Molecular organization: Polarized optical microscopy, infrared spectroscopy, or grazing incidence X-ray diffraction (GIXRD) can assess molecular orientation and packing.

- Surface pressure vs. area isotherms: Confirm monolayer formation and optimum deposition conditions.

Interpretation Notes:

- LB allows layer-by-layer thickness control, while LS emphasizes preserving monolayer integrity.

- Deviations in surface pressure or substrate handling may lead to film defects or incomplete transfer.

4. Example Applications

LB Applications:

- Organic thin-film transistors and molecular electronics.

- Multilayer optical coatings and anti-reflective films.

- Controlled assembly of nanoparticles for sensors.

LS Applications:

- Transfer of biomolecules (lipids, proteins) for biointerfaces.

- Monolayers of sensitive polymers or fragile nanoparticles.

- Research on molecular orientation in single-layer films.